From Manual to Automated: The Evolution of Card Packaging with Packaging Machines

Understanding the shift from manual to automated packaging solutions

Back in the day, packaging was all about people doing everything by hand. Workers had to fill containers, seal them shut, then slap on labels one at a time throughout long shifts. The results? Products coming out looking different each time, production lines grinding to a halt when things went wrong, and payroll expenses climbing through the roof. These days, most facilities run on automated packaging systems that bring together mechanics, electronics, and computer controls into one smooth operation. Companies aren't just chasing faster speeds though. They want precise results that match across thousands of units while keeping their staff safe from those tedious repetitive motions. For manufacturers trying to stand out in crowded markets, investing in automation isn't just smart business it's becoming essential survival.

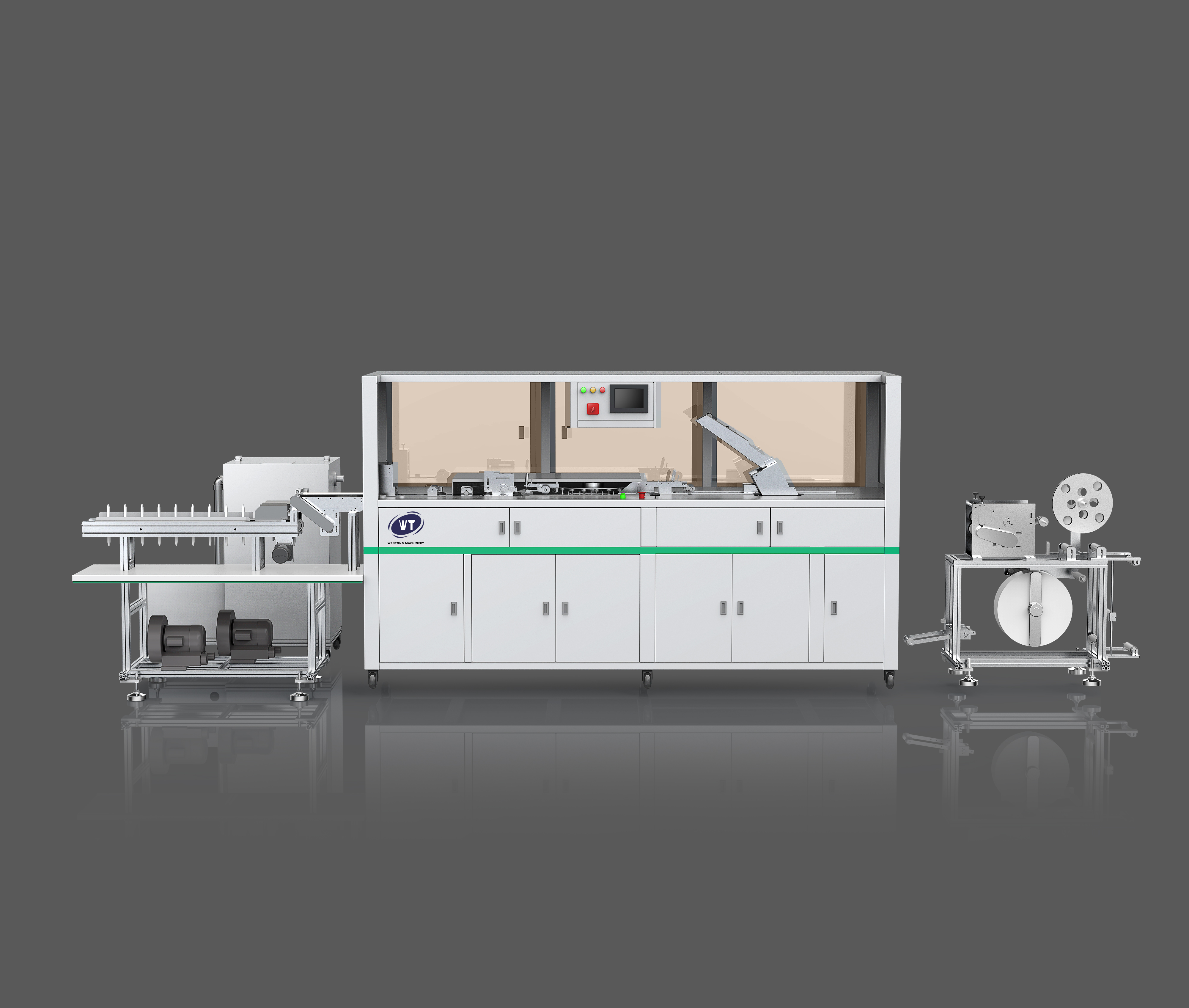

Core mechanics of blister card packaging machine functionality

Blister card packaging machines rely on some pretty advanced engineering to create both secure packaging and attractive displays for products. The basic process starts when plastic sheets get heated until they can be shaped into those little bubble-like cavities we all recognize. After forming these shapes, the material cools down and gets cut to fit specific dimensions. Then comes the actual product loading phase where items go into each blister cavity before attaching them to their printed backing cards through either heat bonding or adhesive methods. Behind the scenes, programmable logic controllers work alongside various sensors throughout the entire operation. These systems watch out for problems like things getting stuck or improper seals while keeping everything aligned properly so every package ends up looking neat and sealed tightly against air exposure. Compared to what humans could manage manually, these automated setups offer much better consistency, especially important for creating tamper evident packages ready straight off the shelf at stores everywhere.

Rising demand for speed and accuracy in modern card packaging

As customers want faster delivery and better quality, plus online shopping keeps growing, businesses really need their packaging to be both quick and precise. Traditional hand packing just doesn't cut it anymore when dealing with the sheer numbers and accuracy demands we see these days. That's why so many companies are jumping on board with automated solutions. These machines can handle massive volumes, sometimes processing several thousand items every hour while making very few mistakes. This cuts down on expenses over time and makes operations run smoother day after day. We're seeing particular interest in sectors like medicine manufacturing, tech gadgets, and big box stores where keeping products safe during transport matters a lot. For manufacturers willing to spend on automation technology, there's definitely an advantage to be had. They get things done faster, scale up production without breaking a sweat, and ultimately keep shoppers happy with consistent results across all orders.

Key Benefits of Packaging Machines in Card Production Efficiency

Increased Speed and Consistency in the Packaging Process

Automated packaging machines significantly outpace manual operations, processing thousands of cards per hour with consistent precision. By eliminating human variability, they ensure uniform seal integrity, alignment, and presentation. High-speed sensors and control systems maintain quality even at peak throughput, minimizing errors and reducing the need for rework.

Cost Savings and Improved Operational Efficiency Through Automation

Automation reduces labor requirements by 30–50%, lowering operational costs. It also cuts material waste dramatically—scrap rates fall from 5–10% in manual processes to under 1% with automated systems. These improvements directly reduce per-unit costs and boost profitability for card manufacturers.

Case Study: ROI Improvement After Integrating Automated Packaging Systems

One major card company saw their money back within just twelve months after installing an automated blister packaging line. Their production output doubled during this period, and they noticed something remarkable too - packaging errors plummeted by almost 95%. What really made a difference was how flexible the new system proved to be. It could work with all sorts of different card sizes and shapes without needing any adjustments or extra equipment. This eliminated those costly secondary packaging operations that used to take so much time and resources, making everything run smoother and saving money across the board.

Blister Card Packaging Structures and Versatility Enabled by Packaging Machines

Overview of blister card packaging types and structural designs

Packaging equipment can handle various blister card setups depending on what's needed for security purposes, how products need to be displayed, and manufacturing requirements. Most standard designs have these pre-made plastic blisters attached to cards via heat sealing after forming a flange around them. This works great for stores looking to keep costs down while still presenting items attractively. Some advanced models go further by adding two layers of material along with better sealing systems that make it harder to tamper with contents and protect against damage during shipping. Getting these machines right matters because poor setup affects how fast things get produced and how customers actually interact with the final package. Choosing materials carefully makes all the difference too since products might spend weeks or months in transit before reaching shelves.

Skin packaging vs. blister packaging: functionality and applications

Blister packaging and skin packaging actually meet quite different needs in the marketplace. Take blister packaging first. It works by forming plastic pockets that get stuck onto stiff cardboard bases. Products sit inside these clear compartments so customers can see them right away. Plus, the seal makes it hard for anyone to mess with what's inside. That's why pharmacies stock their pills this way, and stores display gadgets like that too. Skin packaging does things differently though. The process involves heating up plastic film until it wraps tightly around whatever item is placed on a special board. This creates a tight vacuum seal that holds everything together. Works great for weirdly shaped stuff that just wouldn't fit nicely in regular boxes. Retailers love this for showcasing items on shelves where space matters. Most blister packaging lines run pretty fast since they handle standard-sized products all day long. Skin packaging equipment tends to be slower but much better at handling all sorts of different shapes without breaking a sweat.

How packaging machines support diverse product needs across industries

Today's packaging equipment really opens up possibilities for blister card packaging across different industries. Take pharmaceuticals for instance, where sensors help get the dosage just right and create those secure seals that stop anyone from messing with the contents. When it comes to gadgets and tech stuff, special anti-static materials combined with custom-made spaces keep delicate parts safe during transport but still look good on store shelves. What's interesting about these systems is how flexible they are. Manufacturers can actually flip between making medical devices, computer hardware, or even regular cards all on the same machine base. Just swap out a few tools here and there, tweak some settings in the software, and voila! That's why so many big operations rely on automated blister packaging when they need to produce large quantities of multiple products at once.

Integrated Packaging Lines: Synchronizing Primary, Secondary, and Transit Packaging

Streamlining end-to-end packaging with synchronized packaging machine systems

When packaging operations bring together blister pack creation, carton assembly, and pallet stacking all under one roof, they create what many call an integrated production line. These systems cut down on those frustrating manual handoffs between stages that often slow things down. Instead, everything flows smoothly thanks to automated conveyor belts, lane dividers, and robots that grab products right where they need to go. The whole operation runs through a central control system that lets managers keep tabs on how each part is performing minute by minute. According to industry data from last year's Packaging Efficiency Report, companies that have made this switch typically see their output jump somewhere between 30 and 50 percent while saving around 40 percent on staffing expenses.

Strategy: Maximizing line efficiency through packaging equipment integration

Getting different machines to work together properly means having equipment that can talk to each other using standard protocols such as OPC UA or Ethernet IP. Machines built in modular fashion make it easier to scale operations up or down when products need to be changed quickly. Studies indicate that fully integrated production lines can slash changeover time by around 60 percent, plus boost overall equipment effectiveness (OEE) somewhere between 25% and 35% over separate systems. Some important approaches involve setting up central controls so speeds across the line stay synced, adding visual inspection points at various stages to spot problems before they become big issues, and installing buffer storage areas that keep things moving even when there are holdups further along the process chain. All these methods help manufacturers get better value from their resources without sacrificing the ability to adapt to whatever comes next in production demands.

Future Trends: Technological Advancements in Carton and Case Packing Machines

Innovations in High-Speed Carton and Case Packing for Plastic Card Packaging

Today's carton and case packing machines are getting smart with robotics and AI tech that can handle over 120 packs every minute while keeping cards properly oriented and sealed tight. The best part? These machines come with modular designs that make switching between different card sizes and packaging formats quick and easy, which cuts down on those frustrating production stoppages. For companies dealing with constant new product introductions or the wild swings of holiday season demands, this kind of flexibility isn't just nice to have it's practically essential for staying competitive in today's market.

Data-Driven Insights: Measuring Efficiency Gains in Automated Packaging

Automated systems generate real-time data for continuous optimization. Key performance indicators like Overall Equipment Effectiveness (OEE) typically improve by 15–25% after automation (Packaging Digest 2023). The table below highlights measurable gains:

| Metric | Manual Process | Automated System | Improvement |

|---|---|---|---|

| Output Speed | 40 packs/minute | 120 packs/minute | 200% faster |

| Error Rate | 3% | 0.5% | 83% reduction |

| Labor Cost | $25/hour | $8/hour | 68% savings |

This data supports proactive maintenance, bottleneck identification, and long-term process refinement.

Fully Automated vs. Semi-Automated Systems: Weighing the Pros and Cons

When deciding between full versus semi-automation, manufacturers need to look closely at their production volumes and how flexible they need to be. Full automation setups can crank out massive quantities consistently most of the time, around 99% of the clock actually, and generally just need one or two people watching things during each shift. On the flip side, semi-automated lines give factories more room to handle those oddball orders or smaller batch sizes, though they run at roughly half the speed compared to fully automated counterparts. Looking at what's happening across different sectors, businesses making well over half a million items every month tend to see their investment pay off in about 18 to 24 months when going all-in on automation. But for shops with lower output requirements, sticking with semi-automated equipment often makes better financial sense in the long run.

Frequently Asked Questions

How do blister card packaging machines work?

Blister card packaging machines use advanced engineering to form plastic sheets into bubble-like cavities, then attach products to backing cards with heat bonding or adhesive methods, ensuring consistency and security.

What are the cost benefits of automated packaging systems?

Automated packaging systems reduce labor costs by 30-50%, lower material waste, and improve per-unit costs, making them economically advantageous for manufacturers.

How can packaging machines handle diverse products?

Packaging machines offer flexibility by allowing manufacturers to switch between different products with adjustable tools and settings, catering to various industry needs.

Table of Contents

- From Manual to Automated: The Evolution of Card Packaging with Packaging Machines

- Key Benefits of Packaging Machines in Card Production Efficiency

- Blister Card Packaging Structures and Versatility Enabled by Packaging Machines

- Integrated Packaging Lines: Synchronizing Primary, Secondary, and Transit Packaging

- Future Trends: Technological Advancements in Carton and Case Packing Machines

- Frequently Asked Questions