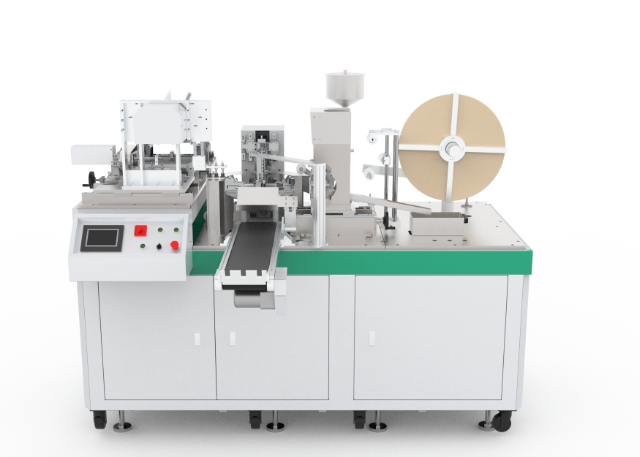

The Role of the Punching Machine in Modern Card Manufacturing

Understanding card body punching and its significance

Punching out the card body remains one of the most important steps when making standard cards that actually work properly. These days, modern punchers can hit around plus or minus 0.05 mm accuracy, which means all those thousands of cards come out looking pretty much identical. That kind of consistency matters a lot for things like credit cards, employee IDs, and security passes where every detail counts. Without this level of precision, there would be all sorts of problems with uneven edges that might mess up how machines read them at stores or building entrances.

How punching machines enable precision in card shaping

Modern servo driven punch systems can deliver varying forces all the way up to around 3,000 Newtons, making them suitable for working with materials such as PVC or those PET-G composite types commonly used in manufacturing. The system uses laser guidance for positioning which keeps errors below five microns even at top speeds, something that really matters when dealing with layered cardstock where layers might otherwise come apart. When operators switch from handling standard smart cards that are about 0.76 mm thick to thicker RFID badges measuring approximately 1.2 mm, the machine's advanced sensors take over and tweak the cutting settings automatically. This means no need to stop production for manual adjustments while still getting consistent results across different product types.

Integration of punching technology in automated production lines

Top manufacturers are now combining punching machines with robotic material handling systems, which helps them maintain around 98.7% uptime during operations. When it comes to changing between different card types, these automated systems can tweak the punching depth on their own, slashing changeover times down about 80% or so compared with what used to take place manually. The real game changer though is how they monitor quality in real time through built-in vision tech. This setup spots bad cards halfway through the process and pulls them out before they waste anything else. As a result, factories report roughly 35-40% less material going to waste during those long production cycles.

Maximizing Production Efficiency with Advanced Punching Machines

Reducing Cycle Time Through High-Speed Punching Operations

The latest generation of punching machines can punch through cards at an impressive rate of just under a second per unit thanks to their servo driven systems, which means they're capable of producing around 3,600 punched items every single hour. For businesses in sectors such as banks or stores running customer reward schemes, this kind of speed really matters since typical orders tend to be massive batches well above the 50k mark. What makes these machines so efficient? They feature dual head setups that switch back and forth between working on one side while resetting the other, basically cutting any idle time down to nothing. Industry insiders know that this continuous operation is what keeps production lines humming along without those frustrating stop gaps that slow things down.

Automated Punching Systems Increase Output by up to 60%

According to recent industry data from 2025, factories using automated punching systems see their production capacity jump anywhere between 52% to almost 70% over traditional manual methods. Take for instance a smart card manufacturing plant that saw its daily output skyrocket from just 18 thousand cards to nearly 29 thousand within an 8 hour workday once they switched to vision guided automation. What's really impressive is how these machines keep things aligned within plus or minus 0.05 millimeters even when running flat out, which means products stay consistently good quality no matter how many thousands get produced day after day without breaking a sweat.

Minimizing Material Waste With Optimized Die Designs

Steel dies cut using laser technology that maintains tolerances at the micron level can bring down scrap rates to below 3%, which is pretty impressive for manufacturing standards. When tool shapes are optimized through finite element analysis, the cutting forces get distributed much more evenly across the material. This not only makes the tools last around 40% longer than standard ones but also stops the workpiece from warping during processing. The computer programs used for CAD/CAM nesting do an amazing job placing blanks on PVC and PET sheets, getting material usage up between 93% and 96%. That kind of optimization really cuts costs in production environments where every bit of raw material matters.

Case Study: Smart Card Factory Efficiency Gains

One ID card maker in Germany saw their costs drop by nearly 30% when they switched to servo driven punch presses. Their new system came packed with some pretty impressive tech upgrades. The RFID smart tools slashed setup times between jobs by around three times what they were before. They also installed regenerative brakes which helped reduce overall power consumption by about 19%. Another neat feature was the real time thickness adjustment that automatically compensated for differences in material batches during punching operations. With all these improvements, the factory could now produce 37 distinct card formats on the same line without anyone having to manually adjust anything between runs.

Ensuring High Card Quality Through Precision Punching Technology

Maintaining edge consistency and dimensional accuracy

Today's punching machines can hold tolerances around plus or minus 0.05 mm, which makes all the difference for things like contactless payment cards and ID badges where precision matters. These machines use servo driven systems that adjust on the fly when materials vary in thickness, keeping those edges straight even through different materials like PVC, PET, and various composites. Manufacturers also rely on laser guided alignment combined with multiple stage tools to eliminate those tiny burrs along the edges. Why does this matter? Well, according to industry reports from Smart Card Alliance back in 2023, about one out of every five returned cards had problems with edge quality. Getting these details right isn't just about meeting specs but actually reducing waste and returns in production.

Preventing delamination and surface damage during punching

The precision of the punching process stops layers from separating because it adjusts pressure dynamically, which matters a lot when making hybrid cards that include RFID antennas or security foils inside them. Using temperature controlled dies helps cut down on heat damage to materials, and vacuum ejection systems make sure parts come out without any surface scratches after they're removed from molds. When manufacturers implement adaptive depth controls for punching operations, they see about a 60 percent drop in delamination issues according to recent benchmark studies from 2024. This kind of improvement means better overall yields and fewer rejected products at production facilities.

Balancing speed and quality in high-volume punching runs

The best producers manage to get under 0.2 defects for every million cards produced while running machines at rates above 8,000 pieces per hour. They do this through several key technologies working together: real time visual inspection systems, cutting tools made from self sharpening tungsten carbide that last well beyond two million operations, plus smart software that automatically compensates when material thickness varies. These capabilities allow companies to produce massive quantities without sacrificing quality standards. Take the recent automotive loyalty card project launched in early 2024 as proof. That operation hit nearly perfect results with just 99.998% good parts on the first try across 15 million cards manufactured each month, maintaining dimensional accuracy within plus or minus 0.1 millimeters throughout.

Enabling Customization and Personalization with Flexible Punching Solutions

Creating Unique Shapes and Cutouts for Brand Differentiation

Today's punching machines can handle all sorts of unusual card shapes from circles and hexagons right down to weird asymmetrical designs that really stand out and boost brand recognition. According to research published in the Card Market Analysis for 2023, companies that went beyond the usual rectangular loyalty cards actually retained customers at a rate 27 percent higher compared to their competitors still stuck with boring old rectangles. The latest multi axis CNC punching tech makes these complex cuts possible with incredible accuracy around plus or minus 0.05 millimeters. This level of detail opens up some pretty cool security options too, such as those fancy puzzle piece gift cards where each fragment fits together perfectly but looks totally random on its own.

Supporting Rapid Prototyping and Small-Batch Custom Card Production

With servo driven systems, setup time drops below 15 minutes so manufacturers can actually try out around six to eight different prototypes each workday. Using 3D printed dies makes it possible to produce runs starting at just 100 pieces, which cuts costs by about three quarters compared to old school tooling methods according to those 2024 Flexible Manufacturing Trends reports we've been seeing lately. What this really means is companies can experiment with fancy stuff like holographic effects or intricate textures on their products long before they commit to mass production runs.

Case Study: Limited-Edition Gift Cards With Intricate Punched Patterns

A premium stationery brand used programmable punching systems to produce holiday gift cards featuring 212 laser-cut snowflake perforations each. The system maintained <0.1mm positional accuracy across 20,000 units and achieved a 99.2% defect-free rate. The limited series sold out within 72 hours, delivering 40% higher margins than standard products.

Future Trend: AI-Guided Punching for Dynamic Design Adaptation

Next-generation systems use machine learning to optimize punch paths in real time, reducing material stress by 18-22% during complex cuts. According to a 2023 survey by Manufacturing Tech Weekly, 61% of card producers plan to adopt AI-assisted punching by 2025 to support evolving design demands like gradient perforations and adaptive security cutouts.

Adapting to Market Demands with Smart and Scalable Punching Systems

Scaling punching capacity to meet fluctuating market needs

Modular punching machines allow manufacturers to scale output from 5,000 to 500,000 cards daily without mechanical overhauls. Servo-driven models reduce tooling changeover times by 50% compared to traditional systems (IoT Business News 2025), enabling rapid transitions between standard ID cards and specialized formats like gaming or event access cards during peak demand.

Multi-material compatibility: Handling PVC, PET, and compostable substrates

Advanced systems process over 12 material types using intelligent force adjustment. A single machine can seamlessly switch between rigid 0.76mm PVC for payment cards, flexible 0.3mm compostable PLA for eco-loyalty cards, and multi-layer PET composites for RFID badges. This versatility improves efficiency by 60% when fulfilling mixed-material orders (Smart Manufacturing Journal 2024).

IoT-enabled punching machines for real-time performance monitoring and adjustment

Punching machines connected to the cloud now use industrial internet of things tech to spot when tools are wearing out by analyzing vibrations, figure out better punch sequences based on real time orders coming in, and tweak settings as temperatures change around them. Factory workers get warning signs about possible breakdowns as early as three days ahead of time. This has cut down unexpected stoppages by almost nine out of ten cases at plants where these intelligent systems are running according to what was published in the Industrial Automation Report for 2025.

FAQ

What types of materials can modern punching machines handle?

Modern punching machines can process various materials like PVC, PET, PET-G composites, and even compostable substrates such as PLA. They are capable of adjusting forces automatically to deal with different types of materials.

How do punching machines maintain high accuracy?

These machines use servo-driven systems and laser-guided alignment to ensure accuracies within plus or minus 0.05 millimeters. This allows them to maintain dimensional accuracy and edge consistency.

What are the benefits of integrating punching technology with automation?

Automation increases production efficiency by enabling higher speeds, reducing manual changeover times, and ensuring real-time quality control, thereby reducing material waste and improving uptime.

How do AI and IoT technologies contribute to modern punching systems?

AI and IoT technologies facilitate dynamic adjustments and real-time performance monitoring. This helps in optimizing punch paths, reducing material stress, and minimizing unexpected downtimes.

Table of Contents

- The Role of the Punching Machine in Modern Card Manufacturing

- Maximizing Production Efficiency with Advanced Punching Machines

- Ensuring High Card Quality Through Precision Punching Technology

- Enabling Customization and Personalization with Flexible Punching Solutions

- Adapting to Market Demands with Smart and Scalable Punching Systems

- FAQ