The diversity and uniqueness of materials are becoming increasingly important for companies in the global printing and packaging, advertising production, and educational supplies production industries to maintain their competitiveness. Different materials have different winding requirements. For example, the winding requirements of paper materials such as posters and learning cards are very different from those of special materials such as EVA and plastic films. Traditional standardized paper winding machines are difficult to replace, resulting in low production efficiency and inconsistent product quality. We are a PVC paper winding machine R&D and manufacturing company based in Shenzhen, China, and are very active in the global overseas market. We have been in this industry for more than ten years, focusing on customized PVC paper winding machine solutions. The poster paper winding machine specially designed for materials such as posters, study cards, and EVA has become the preferred equipment for many foreign companies. This article will discuss how to create an efficient and reliable paper roll machine for special materials from the three perspectives of solutions, customization process, and successful cases.

The demand for paper roll machines in foreign markets has long broken through the bottleneck of "generalization." The equipment has to deal with many different problems, such as uneven thickness of printing and packaging paper, easy stretching of plastic film, different multi-layer structures of composite materials, and strict requirements for flatness of roll products such as posters and learning cards. The efficiency of manual rolling mode is only 1/5 of that of automatic equipment. In addition, the manual operation force is inconsistent, which can easily cause problems such as material wrinkling and uneven edges. This will directly affect the appearance of the product. At the same time, merchants are also facing the problem of rising labor costs. In order to solve these problems, our customized PVC roll paper machine (including the poster roll paper machine) has five competitive advantages.

The biggest advantage of our equipment is its high speed and high degree of automation. The equipment adopts a servo motor drive system and a PLC intelligent control system, and the whole process from feeding and tension adjustment to winding is fully automated. The winding speed of a machine can reach 800 to 1,200 meters per hour, which is five to eight times that of manual winding. This greatly shortens the production time for merchants. An overseas advertising company uses a poster paper winding machine to wind many different types of poster materials every day. After the automatic equipment was put into use, the paper rolling process, which used to require eight workers, can now be completed by only one operator, and the daily output has increased by three times.

The ability to control precisely solves the main problem of winding special materials. As paper materials such as posters and learning cards are easily damaged and plastic films are easily stretched, we have added high-precision tension sensors and dynamic adjustment systems to the equipment. The tension control accuracy can reach ±0.1 N, and the winding force can be changed in real time according to the thickness and characteristics of the material to ensure that there are no wrinkles, stretching, or other phenomena during the winding process. The infrared positioning device of the equipment can also perform edge alignment with an accuracy of ±0.5 mm, which can fully meet the requirements of posters, high-end packaging, and other products with strict requirements on appearance quality.

Because it can handle so many different materials, one machine can handle many different materials. Our custom PVC paper roll winding machine can handle a wide variety of materials, including composite materials, printing and packaging paper, plastic film, and EVA. By replacing the adjustable winding shaft and paper pressing mechanism, the winding mode of different materials can be quickly switched. In particular, the poster paper roll paper machine is just right in the setting of paper roll speed and pressure in view of the waterproof and film-covered characteristics of poster materials. It can handle ordinary coated paper posters and thickened laminated posters, truly achieving "one machine for multiple purposes."

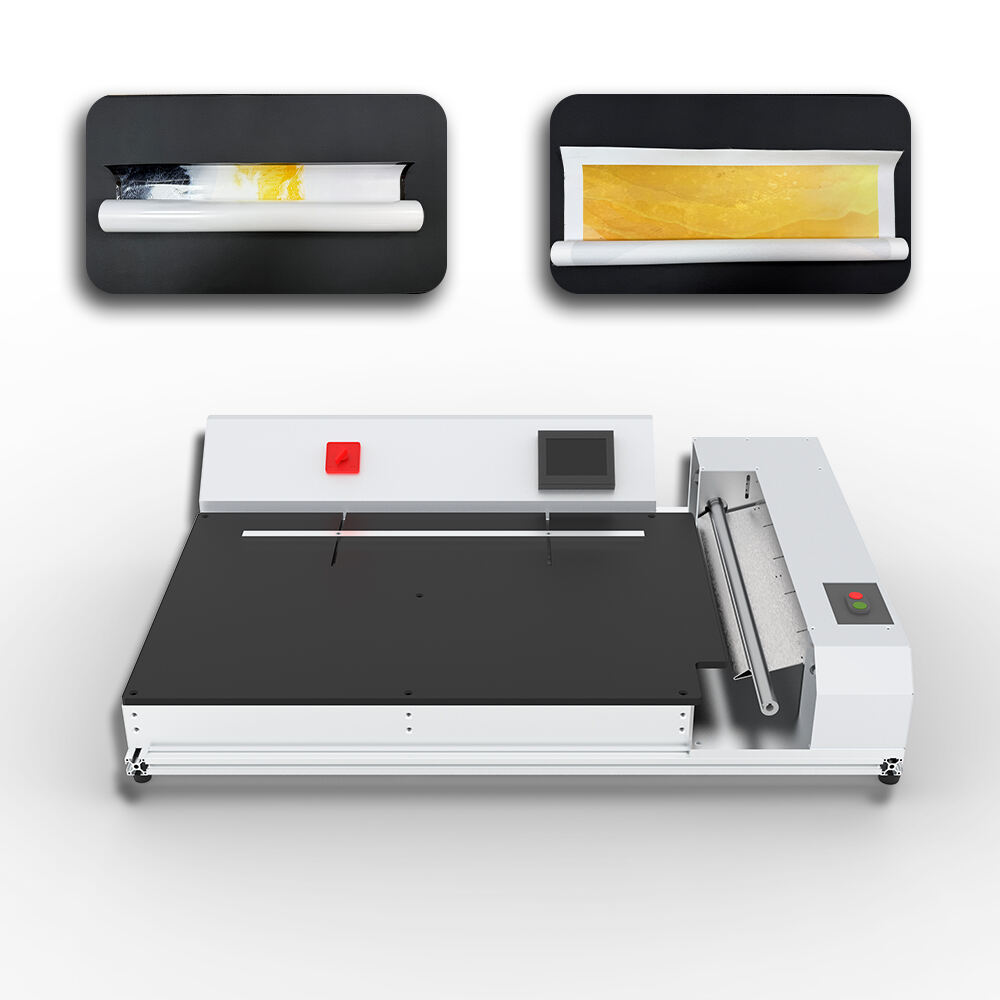

The simple operation and highly adaptable winding design make it more convenient to use. The equipment is equipped with a 7-inch touch screen, and a winding parameter template for a variety of commonly used materials is built in. The operator only needs to select the type and specification of the material to automatically match the best parameters. New employees can start working after one hour of training. It can also wind one or more materials at the same time. The number of winding turns is variable, which can meet the small batch production needs of posters and learning cards of different specifications. This helps avoid material waste and makes production more flexible.

Customization is not just about changing settings but a full-cycle service from demand mining to after-sales guaranty. We have established a set of standardized customization processes to ensure that each device meets the personalized needs of customers while ensuring that the equipment can be successfully exported and the user experience is good.

We will arrange one-on-one video calls and on-site inspections (key markets) with customers by professional technical engineers to fully understand the material characteristics of customers (such as thickness, width, and material hardness), production scale, winding specification requirements, existing production pain points, etc. We provide technical support in multiple languages for customers in other countries. At the same time, we use local voltage standards, workshop space requirements, and other information to produce detailed demand research reports.

During the scheme design stage, the technical team will carry out the design work under the guidance of the survey report. They will also use CAD 3D modeling to display the equipment structure and produce detailed technical solutions, including equipment parameters, core configuration, customized parts design, expected production effect, etc. For example, a layered tension control system was specially made for the multi-layer winding of composite materials. In response to the flatness requirements of poster winding, the material of the paper pressing roller and the pressure adjustment range were improved. After the plan is determined, it is necessary to contact the customer again and modify and improve the plan according to the customer's feedback until everyone is satisfied.

During the prototype manufacturing and testing phase, we first manufacture the core customized parts and test them separately. Then we assemble the entire machine and test the linkage. The tests include important indicators such as the winding effect of different materials, the effect of tension control, and the effect of edge alignment. We also conduct 72-hour continuous running tests in a simulated production environment to ensure the stability of the equipment. Customers will receive a report with test data, and they can watch the test remotely or send someone to the site for acceptance.

In the mass production and delivery stage, we strictly follow the ISO9001 quality system standards for production. To ensure the reliability of the equipment, key components are imported brands, such as Siemens servo motors, Schneider control systems, etc. For international customers, we provide door-to-door delivery service. We are responsible for customs declaration, transportation, on-site installation, and commissioning. We also sent engineers to train the customer's personnel on how to use the equipment and perform daily maintenance.

During the after-sales warranty period, the global technical support hotline is open 24 hours a day. Customers in other countries can get technical help the first time through telephone, video, and other ways. The equipment is provided with a one-year free warranty, and the main parts are provided with a two-year warranty. At the same time, spare parts warehouses are built in important markets such as Europe and North America. This will ensure that maintenance spare parts can be delivered quickly and keep customer downtime to a minimum.

A well-known European high-end packaging supplier is an Italian printing and packaging company. It mainly produces multi-layer composite packaging materials for high-end products such as food and cosmetics. We also want to make printed materials such as posters and brochures. In the past, the company's composite materials and poster materials were all manually wound. Not only is the speed slow, but also due to the multi-layer structure of the composite material, the tension is uneven, and delamination and wrinkling are prone to occur after winding. The poster edges were uneven, and the customer was not satisfied. There was an urgent need to customize paper winding equipment.

After receiving the demand, our technical team first checked the composite material (three-layer PET+ aluminum foil+PE) and poster material (200g coated paper with film) produced by the company. It was found that the thickness deviation of the composite material was ±0.02 mm, the aluminum foil layer was easily damaged, and the surface of the poster material was smooth and easy to slip after being covered with film. In response to the company's request that "one device can be compatible with two materials at the same time, and the winding speed should reach at least 1,000 meters per hour," we proposed a special solution.

In terms of core configuration, the composite material adopts three sets of independent tension control systems. These three systems correspond to the unwinding tension adjustment of the three layers of base material, respectively, ensuring the tension synchronization during multi-layer compounding. In order to solve the problem of slipping of poster materials, the texture design of the rubber pressure roller was improved to increase the friction and protect the film surface. It also has a dual-position take-up mechanism, which automatically switches to the other position after one roll is finished. This reduces the time spent changing rolls and speeds up continuous production.

After the equipment was delivered, the delamination rate of composite material winding was reduced from 15% to 0 after on-site debugging. The edge alignment accuracy of the poster winding is maintained at ±0.3 mm, and the winding speed reaches 1100 m/h, which is 6 times that of the customer's original production mode. Labor costs have also been reduced by 80%. The customer's high-end packaging and poster products have seen the pass rate increase from 82% to 99.5% after using the equipment. The customer subsequently received long-term orders from many international brands. Now, the customer has purchased three pieces of customized equipment from us and become our most important partner in the European market.

As a PVC paper roll machine customization expert for the global market, we always take "material adaptability" as the core of our work. We solve the unique winding problems faced by different industries with the core advantages of high-efficiency automation, precise control, and wide adaptability. We can customize solutions for any material, including paper materials such as posters and learning cards, as well as special materials such as plastic films and composite materials. If you are troubled by the winding of non-standard materials, please contact us. Our custom equipment can help you increase production efficiency.