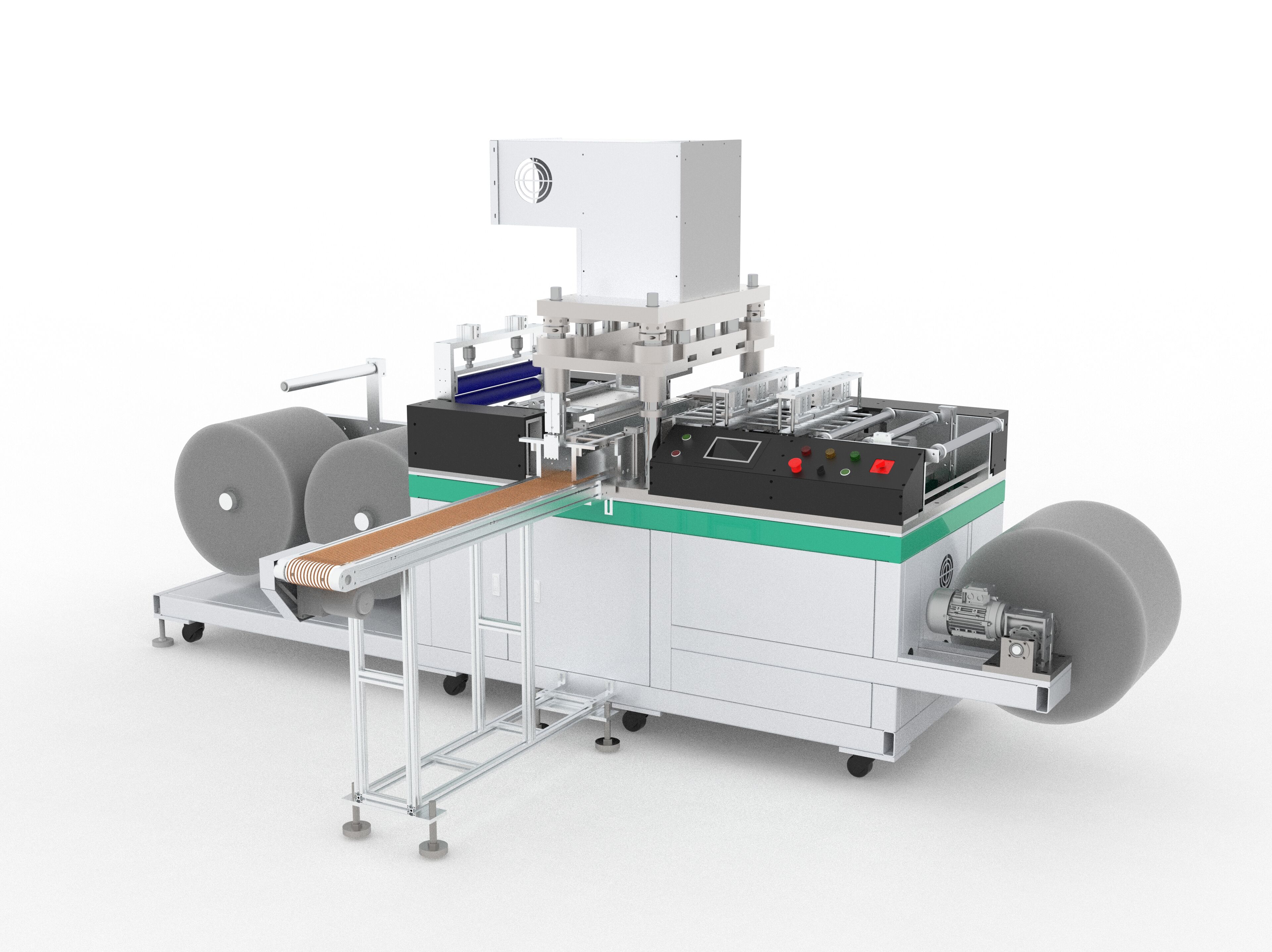

Shenzhen Wentong Machinery has been focusing on punching and cutting equipment for 20 years, especially in the punching and die-cutting of sheet products such as cards, books, labels, refrigerator magnets, filter paper, steamed bun paper, etc. Today I will talk about the roll die-cutting machine, which is designed for filter paper. Replacing the mold can also be applied to more products such as baking paper steamed bun paper, silicone oil paper, and even non-woven fabrics.

The roll die-cutting machine is a professional equipment for die-cutting rolled raw materials.

1. Unwinding: The equipment first unwinds the rolled materials such as paper, plastic film, metal foil, etc. smoothly and conveys them to the processing area through the unwinding device. The unwinding device is usually equipped with a tension control system to ensure that the material maintains a constant tension during the conveying process to avoid relaxation or excessive stretching, which affects the die-cutting accuracy.

The unwinding group is one of the most important components of this automatic roll to sheet filter paper production line. Its core advantage is the intelligent tension control system of the unwinding device. The system monitors the tension of the coil in real time through advanced sensors. With its precise tension control, the material is always flat and stretched, ensuring the smooth progress of the subsequent die-cutting process. This stable tension control not only improves the qualified rate of the product, but also greatly reduces the cost increase caused by material loss.

During the conveying process, the coil is very likely to deviate, affecting the die-cutting accuracy. The high-precision correction technology equipped with the unwinding device uses visual recognition and sensor dual detection to achieve a correction accuracy of 0.1mm. When the coil is detected to be offset, the system will quickly drive the correction mechanism to automatically adjust to ensure that the coil is always accurately conveyed along the preset path. Complex shapes and strict size requirements pose great challenges to coil positioning, and the correction technology of the unwinding device can ensure that every die-cutting is accurate, effectively avoiding the generation of waste caused by offset, and improving the overall quality and consistency of the product.

In addition, our unwinding device adopts a modular design concept and has the function of quickly changing the reel, which greatly shortens the roll changing time. At the same time, the optimized mechanical transmission system reduces the running resistance and energy loss, making the unwinding speed faster and more stable. In addition, the unwinding device can also achieve seamless docking with the subsequent die-cutting unit. Through intelligent linkage control, it can realize fully automated continuous production from unwinding to die-cutting, greatly improving production efficiency. Whether it is large-scale batch production or small-batch, multi-variety flexible production, it can be easily handled.

2.If unwinding is the "hero behind the scenes" that determines production quality and efficiency, the die-cutting group is the "heart" that directly gives the material form and value.Die-cutting means that when the coil is conveyed to the die-cutting area, the die installed on the die-cutting machine starts working. The die punches or cuts the coil by pressure according to the preset shape and size. Common die-cutting methods include flat-press flat die-cutting, round-press flat die-cutting and round-press round die-cutting.

This automatic roll to sheet filter paper production line uses a flat die-cutting method, which includes two die cutting sets for hole punching and shape die-cutting to complete production of hollow and special-shaped complex products.

The core advantage of flat die-cutting lies in its extreme control of precision. Through the extremely rigid parallel die base structure, the upper and lower dies achieve completely parallel contact when closed, and with the high-precision linear guide and ball screw transmission system, the positioning accuracy can reach ±0.1mm.

Flat die-cutting shows strong adaptability when handling complex processes. For products with composite processes such as hollowing, special-shaped contours, and local indentations, it can complete multiple processes at one time through customized mold design. For example, in the field of high-end gift packaging, special-shaped cutting, three-dimensional embossing and dotted line easy-tear processing of cardboard can be realized at the same time, greatly improving production efficiency.

Although there is a speed bottleneck in flat die-cutting in traditional cognition, the innovation of modern technology has greatly improved its production efficiency. The new servo drive system, combined with a high-speed response hydraulic device, shortens the opening and closing cycle of the mold to 0.8 seconds, and the maximum production speed can reach 200 times/minute. At the same time, the linkage between the intelligent feeding system and the visual positioning system realizes the precise conveying and real-time deviation correction of the coil, and can ensure the position accuracy of each die-cutting even at high speed.In the mass production scenario, the modular design of the flat die-cutting machine further improves efficiency. By quickly replacing the die unit, the switching of different product specifications can be completed within 15 minutes, meeting the flexible production needs of small batches and multiple varieties.

3.Rewinding and waste handling: After die-cutting is completed, the finished materials are neatly stacked through the silo device for subsequent packaging and transportation. At the same time, the waste generated during the die-cutting process is collected and cleaned up in time after being cut by the cutter to ensure a clean working environment and reduce the impact of waste on production.

We have more custom options for die cutting solution. Don’t hesitate to reach out if you need more information.