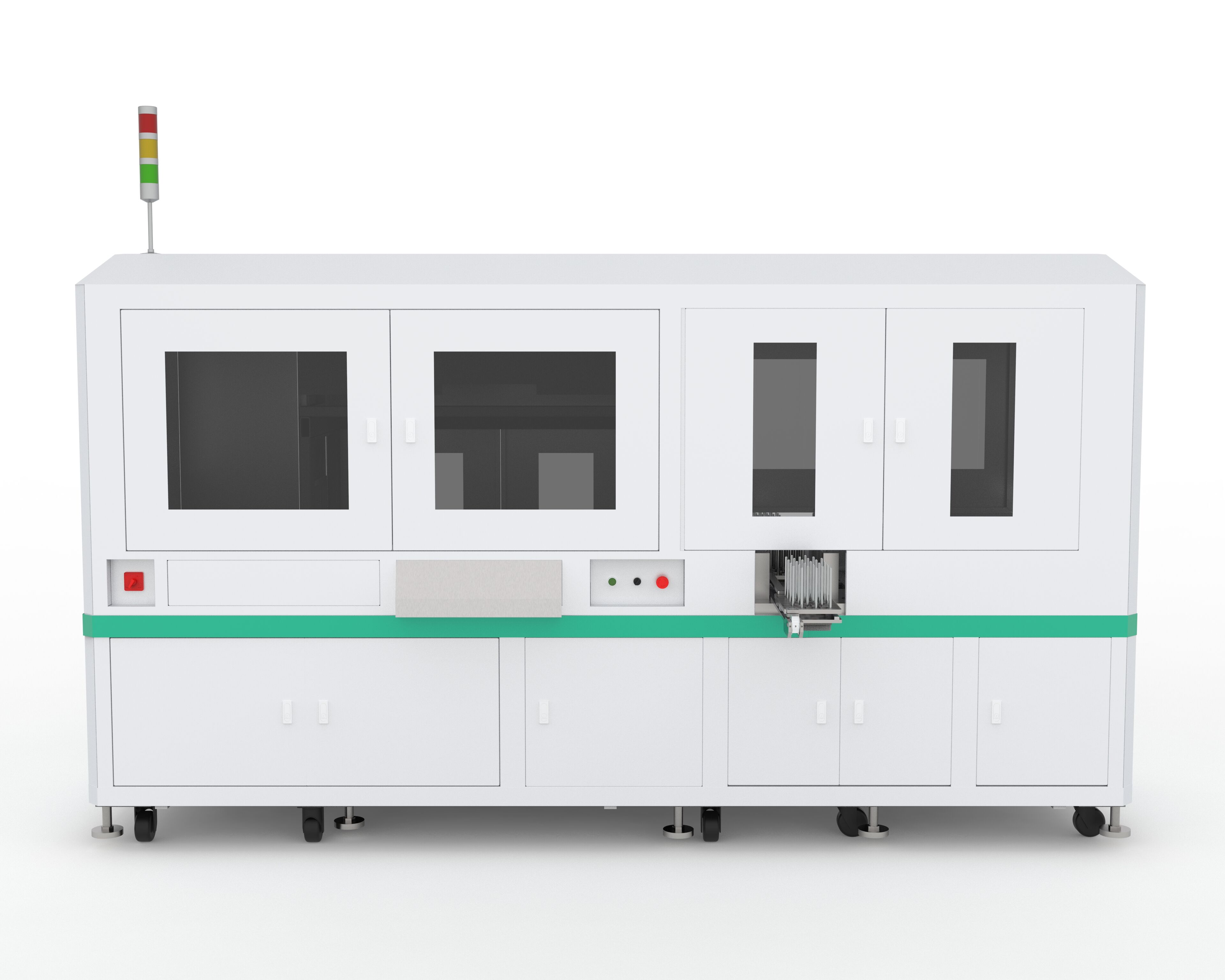

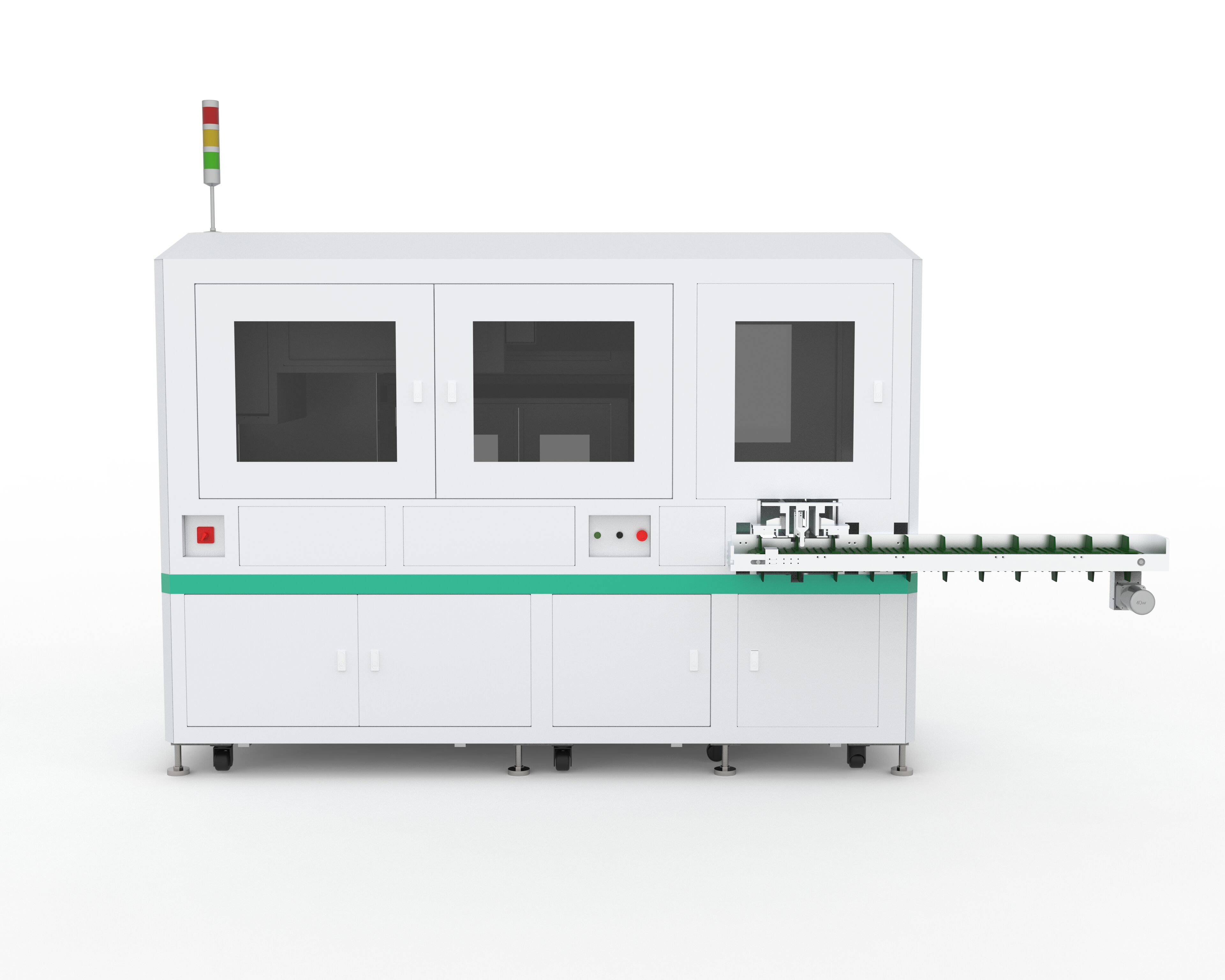

In the card manufacturing industry, game card die-cutting machines are essential for maintaining production efficiency and ensuring the quality of output. The machine is used to produce game cards, membership cards, smart cards, and even metal, wood and plastic cards. Moreover, the most advanced die-cutting machines are now equipped with automatic sorting and separating systems. This improvement has placed higher demands on precision die-cutting. This highlights our understanding of the importance of equipment stability. For our customers around the world, this article identifies and analyzes the three most common problems with game card die-cutting machines and provides the best and most actionable answers to help you reduce downtime and keep production running.

There are many forms of die-cutting displacement, including different sizes of cut cards, burrs on the edges, and misaligned patterns. This type of fault often leads to the waste of raw materials such as metal cards and plastics. This seriously affects automated sorting, causes a backlog of unsorted materials, and increases the defect rate.

The long-term production movement of the equipment caused the bolts to loosen, resulting in a slight displacement of the mold.

The common reasons for the decline in the accuracy of the feeding system are the loosening of the conveyor belt and chain, the wear of the feeding roller or the presence of debris on the surface, which leads to inaccurate feeding.

For equipment with a vision system, the common problems are: foreign matter on the lens or changes in brightness will cause inaccurate positioning.

Safety: Full shutdown and power off.

For die-cutting equipment, refer to the equipment manual. The horizontal (X-axis) and vertical (Y-axis) positions of the die should be re-adjusted using the optical alignment system. Device-specific alignment tools can help with this. Bolts should always be tightened in a diagonal sequence to achieve an even distribution of tension.

In order to reduce unnecessary waste, some scraps can be used for trial die-cutting until the game card is accurately die-cut to the appropriate size.

Systematic inspection of the feeding mechanism:

Check and adjust the tightness of the conveyor belt and chain to the appropriate value according to the specified value in the operation manual.

Use isopropylamine and a dust-free cloth to carefully wipe the dust and oil on the feed roller and pressure roller.

During the use of the equipment, we should regularly clean the lens and reflector of the sensor of the equipment, and check whether the electrical connection is firm.

Every time production starts, a trial run is conducted to ensure that the parts are aligned correctly, thus preventing problems before they occur.

Equipment can indicate problems thru abnormal sounds. For example, your game card die-cutting machine, when the machine is running, there is a rhythmic knocking sound, a dull friction sound or a sharp hissing sound, there may be problems with the core transmission components such as bearings and gears.

In-depth analysis of the root cause of the problem:

Insufficient lubrication or wear of bearings:

Bearings play a key role in the production process of equipment. They are always in high-speed motion. If there is a lack of oil, it will lead to friction loss, high temperature and abnormal noise, and finally lead to seizure.

Worn gears or improper gear mesh:

The gear tooth surface will also be worn after the equipment has been in production for a long time, which will lead to the gap of the tooth surface being too large or too small, so impact noise will be generated during the transmission process.

Loose connection parts:

Loosening of key connecting parts such as couplings and keyways will cause abnormal impact and vibration between parts.

Foreign body intrusion:

If foreign objects (plastic or metal) fall into the gearbox and guide rail during the production of the equipment, scratching noise will be generated during its movement.

Accurate solutions and steps:

Locate the sound source:

When the machine is on, we can use a screwdriver or other tools to get close to the bearing position and determine the position of the abnormal sound thru contact.

Maintenance and replacement of bearings:

Lubrication:

If the inspection confirms that the equipment is short of oil, we should immediately add oil to the designated position of the equipment.

Replacement:

Of course, if there is still abnormal noise after refueling, we can try to rotate the bearing. If there is still jamming, we should immediately stop the machine and replace the high-precision bearing of the same model.

First, we need to open the gearbox or side cover to check the wear of the gears and use a feeler gage to measure the gear meshing clearance value and adjust it to the best. If the wear is too severe, it should be replaced immediately.

Check the fasteners and links of the whole equipment, clean up the foreign matters in the equipment, and ensure that there is no residue of foreign matters.

Strictly carry out periodic maintenance according to the operation manual, and record the maintenance date for later query.

Cards that are not completely punched due to uneven pressure need to be removed manually, which can easily cause over-cutting and damage the material below the card. This is most challenging for multi-layer composite smart cards and high-hardness wooden cards.

The long-term operation of the equipment may cause slight deformation of the die-cutting platform.

The shims are worn, mismatched in hardness, or unevenly installed, and cannot effectively distribute the pressure.

Unstable pressure system:

Pressure fluctuations in the hydraulic system, insufficient air pressure or failure of the pressure regulating valve will cause the pressure output to be unstable.

Poor mold balance:

The die itself is not flat, resulting in uneven pressure at each point.

Accurate solutions and steps:

Calibrate the die-cutting platform:

The flatness of the multi-point detection platform is detected by high-precision level and dial indicator. If the deformation is found to exceed the tolerance range, do not repair or grind it by yourself, and contact our company or qualified professionals immediately.

Optimized shim configuration:

Due to the different materials (for example, switching from plastic cards to metal cards), the worn pads must be checked and replaced. Customized pads with different hardness and elasticity should be used. The shims must be dimensionally accurate, installed absolutely flat and free of inclusions.

Stable pressure source:

Check whether the pressure gage reading is stable. This may be due to the quality of the hydraulic oil, the sealing of the oil circuit, or the pressure and filter of the air source. Pressure sensors and gages must be calibrated so that the readings reflect the actual pressure.

Use pressure-sensitive paper. Place it in the die-cutting area and perform simulated die-cutting. This will give you an intuitive pressure distribution map, which is the most effective auxiliary tool for precise adjustment.

Adjusting the pressure is a delicate job. The cycle of "fine-tuning, testing, and fine-tuning again" should be adhered to, and drastic adjustments should be avoided.

Predictive maintenance is based on the failure analysis of the game card die-cutting machine. Accurate description of predictive maintenance is the basis for efficient long-term operation, and it is the key to producing high-quality game cards, membership cards, and smart cards. When you diagnose the faults described here, you can greatly improve the overall efficiency of the equipment. Our mission is to provide customers worldwide with equipment that not only runs well and is reliable, but also with well-documented and professionally presented technical assistance. If you encounter such problems, please feel free to contact our consultants, who will provide you with remote guidance or on-site assistance as needed.