In industries such as card manufacturing and small package processing, the quality and process level of finished products directly depend on the precision, speed, and automation of die-cutting equipment. With the rise of intelligent manufacturing technology, the problems of traditional die-cutting machines, such as slow response to small batch orders, high error rate of manual sorting, and poor multi-specification processing ability, are becoming increasingly prominent. The step-by-step feeding die-cutting machine combines the automatic sorting and classification system with advanced technologies such as precision feeding, visual correction, and intelligent classification. It has become an important tool to solve the above problems, and its technical principle and application characteristics are worthy of further study.

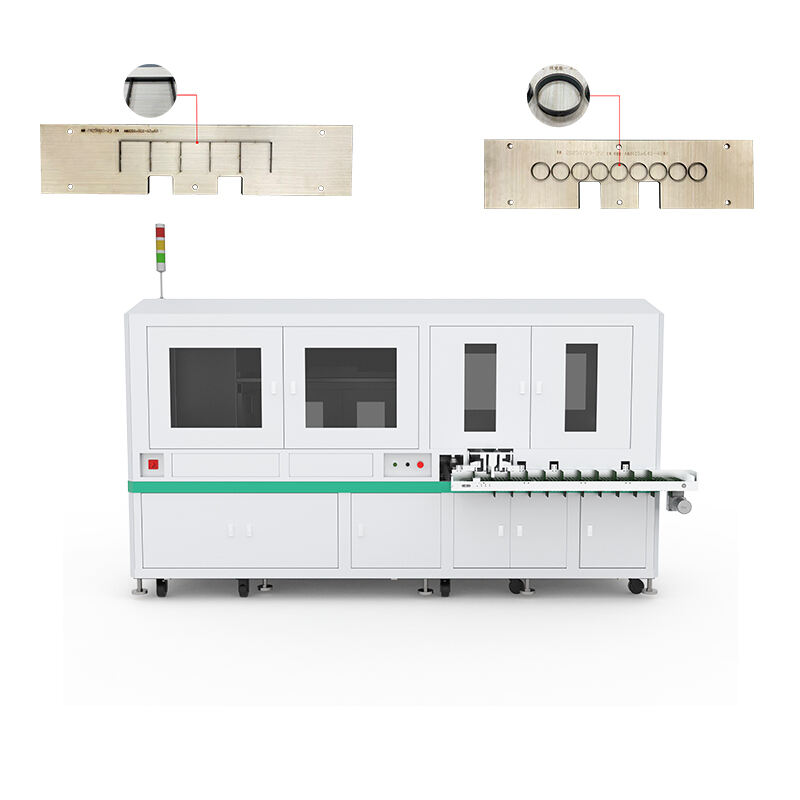

The step-by-step feeding die-cutting machine is a device specially designed for making card products (such as game cards, membership cards, smart cards, etc.) and small boxes for packaging. The main technical advantage lies in the integration of "step-by-step precision feeding + automatic sorting and classification." The equipment can be applied to the surface of different materials such as paper, wood, plastic, film, and soft magnetic sheets. The modular structure design enables multi-process operation. Its technical system includes mechanical transmission, visual detection, servo control, intelligent algorithms, etc. It is a typical representative of the intelligent development of die-cutting machines.

The main factor that makes card production competitive is precision. Especially for playing cards, the patterns must be perfectly aligned, and for smart cards, the chip mounting area must be cut with extremely high precision. The step-feeding die-cutting machine has the best visual correction and positioning system in the industry. It can use high-definition visual sensors to find the material position deviation in real time and cooperate with the 7.5 kW servo punching power system to respond and correct at the millisecond level. It ensures that the die-cutting accuracy is correct from the beginning. The technology enables the position accuracy error of finished products to be controlled within 0.1 mm, and the card edges are smooth and free of burrs, which completely solves the problems of insufficient product accuracy and rework for foreign customers in the past. This is much better than the old equipment that required manual adjustment of the extensive production.

Step feeding is the key to accurate sorting. The technical logic behind it is to break down the previous continuous feeding method into two parts: "intermittent step feeding + real-time position calibration." The equipment adopts multiple sets of servo motors to independently control the feeding roller. The encoder feeds back the real-time information of the feeding distance of each step to the control system. The feeding accuracy can be controlled within ±0.05 mm. In the case of mixed materials of multiple specifications, the system automatically identifies the type and specification of the product through the preset product parameter database (size, material, incision characteristics, etc.) and the real-time image collected by the visual detection module. This enables the system to accurately distinguish products of different specifications. The sorting accuracy rate can reach more than 99.9%. This design fundamentally solves the problem of sorting errors caused by material stretching and movement during the traditional feeding process.

"Nail-free continuous die-cutting technology" is the most important technological progress in die-cutting process equipment. Traditional die-cutting requires the use of nails or connection points to prevent the material from moving. After that, a tearing process is required. The step-feeding die-cutting machine can achieve fixed-point die-cutting due to the dual guaranty of "visual correction + step positioning." The most important technical point is that before die-cutting, the visual system finds the material reference point, calculates the offset, and feeds it back to the servo system. The position of the die-cutting knife holder is changed in real time. The pause interval of each step of feeding during the die-cutting process is perfectly matched with the die-cutting action, ensuring the consistent die-cutting position of each product. This technology not only simplifies the process but also avoids the problem of easy damage to the edges of old-fashioned continuous dot structure products. This keeps the roughness of the card edge below Ra 0.8 μm.

The full-link collaborative control of "die-cutting-detection-sorting" is the technical core of the automatic sorting process. The PLC main controller connects the action logic of the die-cutting unit, the visual inspection unit, and the sorting execution unit. After die-cutting, the conveyor belt transports the product to the inspection station. The vision system quickly collects product images, completes the detection of indicators such as dimensional accuracy and incision quality at one time, and finds product specification information. The detection data is sent to the sorting unit in real time, and the pneumatic sorting mechanism sorts the products into different collection channels according to the preset rules. From die-cutting to sorting and collecting, the whole process does not require manual intervention. The system response time can be as fast as 50 ms, which can completely keep up with the die-cutting speed of 8,000 sheets per hour.

The key to quickly switching between large and small batch production is the quick mold change technology. The stepping feeding die-cutting machine can easily realize task switching due to the modular tool holder design and parametric adjustment system. The equipment has a quick-change die seat structure, which can complete the die change in 5 minutes. During the adjustment process, the product parameters (size, feeding step, die-cutting pressure, etc.) are input through the touch screen. The system automatically calls up the preset parameter template and cooperates with the automatic alignment function of the visual system to control the changeover time of the whole process within 15 minutes. The technology greatly improves the flexible production capacity of the equipment through parametric control and mechanical structure optimization. Traditional equipment needs to be adjusted every two or three hours.

In the finished product collection stage, the equipment can choose to collect in two ways, in order or by category, according to the production needs. The sequential collection mode is used to ensure that cards with consecutive numbers are produced in sequence. The collection mode by category can store products of different types and specifications in different material boxes according to the preset rules and can be directly connected to the next packaging. The 7.5 kW servo punching power system provides you with stable and strong punching force. It can even quickly punch and cut tough materials such as plastic and soft magnetic sheets. The maximum capacity per hour can reach 8,000 sheets, which is much higher than that of traditional equipment.

The long-term value of automated processes is the ability to digitally manage the production process. The step-by-step feeding die-cutting machine can be connected to the MES (Manufacturing Execution System) or ERP system. The equipment collects important information such as die-cutting speed, pass rate, material loss, and equipment load in real time through sensors. Then, this information will be sent to the management system through the industrial Ethernet to form a complete production process record. The system can also automatically send equipment maintenance reminders, consumable replacement warnings, and other information based on production data. It provides data support for preventive maintenance of equipment and meets the technical management needs of intelligent factories.

The equipment can adapt to different materials because it has a modular pressing system and adjustable servo parameters. Due to the different physical properties (hardness, toughness, and thickness) of different materials, the system can make the following technical adjustments: For flexible materials such as paper and wood, the pressure of the feeding roller is reduced, and the anti-skid rubber roller is used to avoid material wrinkling; for rigid materials such as plastic and soft magnetic sheet, the servo punching force is increased (a 7.5 kW servo motor provides stable punching force), and the die-cutting speed is changed to ensure the cutting edge is flat. The equipment can process materials with a thickness of 0.2 to 2.0 mm. By replacing the feed gap adjustment block of different specifications, the substrate of different thicknesses can be quickly adapted without replacing the core components.

The equipment can easily handle a variety of materials, including paper, wood, plastic, film, and soft magnetic sheets. It can also handle materials with a thickness range of 0.2 to 2.0 mm, which is exactly what is needed for die-cutting different materials. For example, when making paper game cards, the equipment avoids paper wrinkling through precise feeding. When making plastic membership cards, the servo stamping system can change the pressure settings to ensure that the edges of the cards are smooth and free of cracks. This ability to work with multiple materials means that one machine can replace several dedicated machines, helping customers save on equipment costs.

"Parametric rapid adjustment + small batch precision molding" shows the superiority of the proofing function from a technical point of view. Traditional die-cutting proofing requires the production of special die-cutting knife plates, which is costly and takes a long time. The stepping feeding die-cutting machine adopts the following technologies to make the proofing more efficient: First, the CNC tool holder is adopted, and the die-cutting track is adjusted through software programming, without the need to make a physical die-cutting knife; second, the feeding system can feed at least 10 small batches of materials at one time to avoid waste; third, the proofing parameters are saved as templates, which can be used again during mass production to ensure that the proofing and mass production processes are consistent. This technology has shortened the previous 1-7 day proofing cycle to several hours, greatly improving R&D efficiency.

An important sign of equipment integration is the ability to connect with the back-end packaging line. The standardized interface design and synchronous control logic are its technical core. The equipment has industrial bus interfaces such as PROFINET and EtherCAT and can be connected with automatic bagging machines, labeling machines, packing machines, and other equipment to perform synchronous actions. The system's main controller ensures that the die-cutting speed is consistent with the operating rhythm of the packaging equipment so that the finished product can smoothly transition from sorting and collecting to the packaging process. The equipment can also change the way of collecting finished products according to the packaging needs. Sequential collection is suitable for products with continuous numbers, and classified collection is suitable for mixed production of multiple specifications. In this way, the same aggregate collection method can be used, and different packaging processes can be adopted.

The core technical components of the step-by-step feeding die-cutting machine are all built according to industrial-grade standards to ensure the stability and accuracy of the equipment. The visual correction system adopts a 2 million pixel high-definition industrial camera and a special image processing algorithm to achieve the position recognition accuracy of 0.01 mm. The feeding and punching system adopts a Siemens servo motor, with a control precision of 0.001 mm and a response frequency of ≥1 kHz. The main controller adopts Mitsubishi PLC, which supports multi-axis linkage control and complex logic operation. The sorting actuator adopts SMC pneumatic components, and the action response speed is ≤30 ms. The high precision and high stability of the equipment are the result of the collaborative work of these core components.

We need to do strict tests to ensure the performance indicators of the equipment are correct. The main test items include the die-cutting accuracy test (measuring the position error of finished products with a micrometer, taking the average value of 1,000 tests at a time), the feeding accuracy test (finding the feeding distance deviation with a laser interferometer), the sorting accuracy test (running continuously for 2 hours, mixing products of different specifications, and finding the error rate), and the changeover efficiency test (recording the time for adjusting the machine to produce products of different specifications). The industry standard stipulates that the finished product position accuracy error of qualified equipment must be less than 0.1 mm, the sorting accuracy rate must be at least 99.9%, and the order change time must be less than 15 minutes. Some high-end models can achieve a die-cutting accuracy of 0.05 mm.

Scientific maintenance methods are the guarantee for the long-term stable operation of the equipment. The main maintenance tasks include regularly checking the accuracy of the servo motor encoder and calibrating it every 500 hours, cleaning the lens and light source of the vision system every week to prevent dust from affecting the detection accuracy, and regularly replacing the feeding roller and die-cutting tool holder according to the wear of the material. The cycle for general paper materials is 2,000 hours, and the cycle for hard materials such as plastics is 1,000 hours. The pneumatic system needs to be drained every day, and the air pressure should be checked regularly to ensure the air pressure is stable. The equipment's self-diagnostic system can detect the status of important components in real time and tell you where the problem is through the alarm code. This makes maintenance easier.

The reason why the stepping feeding die-cutting machine has technical value is that it helps the die-cutting process to transform from "extensive production" to "precision, intelligence, and flexibility." There are three main technical innovations: first, the coordination of stepping feeding and visual correction breaks through the accuracy bottleneck of traditional equipment; second, the automatic sorting and classification system makes the production process unmanned; third, the modular design and parametric control improve the adaptability of the equipment to different situations. These technical features make it useful in the production of cards and small packages, especially suitable for production occasions with small batches, multiple batches, and high precision requirements.

In the future, the technical development of step-by-step feeding die-cutting machines will focus on three directions: first, the in-depth application of AI visual inspection technology, thru machine learning algorithms to achieve autonomous optimization of defect detection and specification recognition, and further improve the accuracy of sorting; second, the energy-saving upgrade of the servo system, the use of permanent magnet synchronous servo motors to reduce equipment energy consumption, and adapt to green manufacturing needs; third, the integration of digital twin technology, thru the construction of equipment virtual models, to achieve simulation optimization and remote diagnosis of the production process. These technological improvements will make the equipment easier to use and help the die-cutting industry achieve intelligent growth.